Why Important

Lighter balconies usually rest on the projecting string course at first-floor level, being fixed to the stonework with lugs which form part of the floor grid, staved into undercut holes.

However heavier balconies are supported on a bracket of cast or wrought iron of various designs. The base and wrought-iron coping rail of the balcony itself are usually built into the wall. Because of the loads they may carry, it is particularly important that balconies be securely fixed to sound stonework, and treated against rust.

It is important that these are well maintained as they provide the embellishment of the building. Being made of cast or wrought iron, they also need careful maintenance to protect them from rust.

Balconies running the length of a street are tied back to the stonework with wrought- or cast-iron bars at the party walls; these ties sometimes take the form of decorative cast-iron panels fixed across the balcony to separate adjoining houses. blah blah

When to look

What to look for

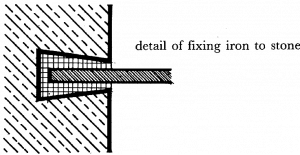

Mostly the bracket is wrought-iron, fixed at top with lug set in lead, fixed at bottom by bolts grouted into masonry.

Mostly the bracket is wrought-iron, fixed at top with lug set in lead, fixed at bottom by bolts grouted into masonry.

Cast iron is particularly brittle and will readily fracture if subjected to tensile stresses or if the section is significantly reduced by corrosion.

The grid floor panels (second image) of continuous balconies need to accommodate a certain degree of thermal and structural movement; welding in situ can restrict movement and cause further cracks.

Water penetration may occur if fixings have been realigned on the wall face, leaving sinkings in the stonework.

Water penetration may occur if fixings have been realigned on the wall face, leaving sinkings in the stonework.

How to fix

Sinkings in the stonework should be made good with a mortar repair.

The hole in the stone is drilled and chiselled to a wedge shape. The balcony is positioned and a clay cup formed beneath to contain the lead. The lead is run in, pared off to the face of the stonework and staved well in. The lead must be sufficiently hot to run to the back of the sinking.

The hole in the stone is drilled and chiselled to a wedge shape. The balcony is positioned and a clay cup formed beneath to contain the lead. The lead is run in, pared off to the face of the stonework and staved well in. The lead must be sufficiently hot to run to the back of the sinking.

An effective temporary repair to a balcony grating floor can be achieved by bolting stainless steel plates above and below the fracture.

Wrought-iron brackets are susceptible to rust and, where seriously weakened by corrosion, should be replaced in stainless steel.